Custom services and R&D expertise in welding and brazing

Chemical and mechanical testing and analysis of welding products

Our laboratory is equipped to carry out chemical and mechanical analyses:

- CCPU 3.1 chemistry and mechanics / CCPU 3.2 chemistry and mechanics certificates (according to EN 10204)

- RCC-M approved products

- Chemical analyses on wires

- Hardness tests: Brinell, Vickers and Rockwell

- Hot and cold tensile tests on wires

- Bending tests

- Impact bending tests (resilience test)

- Macrographies and micrographies

- Customized tests according to your specifications

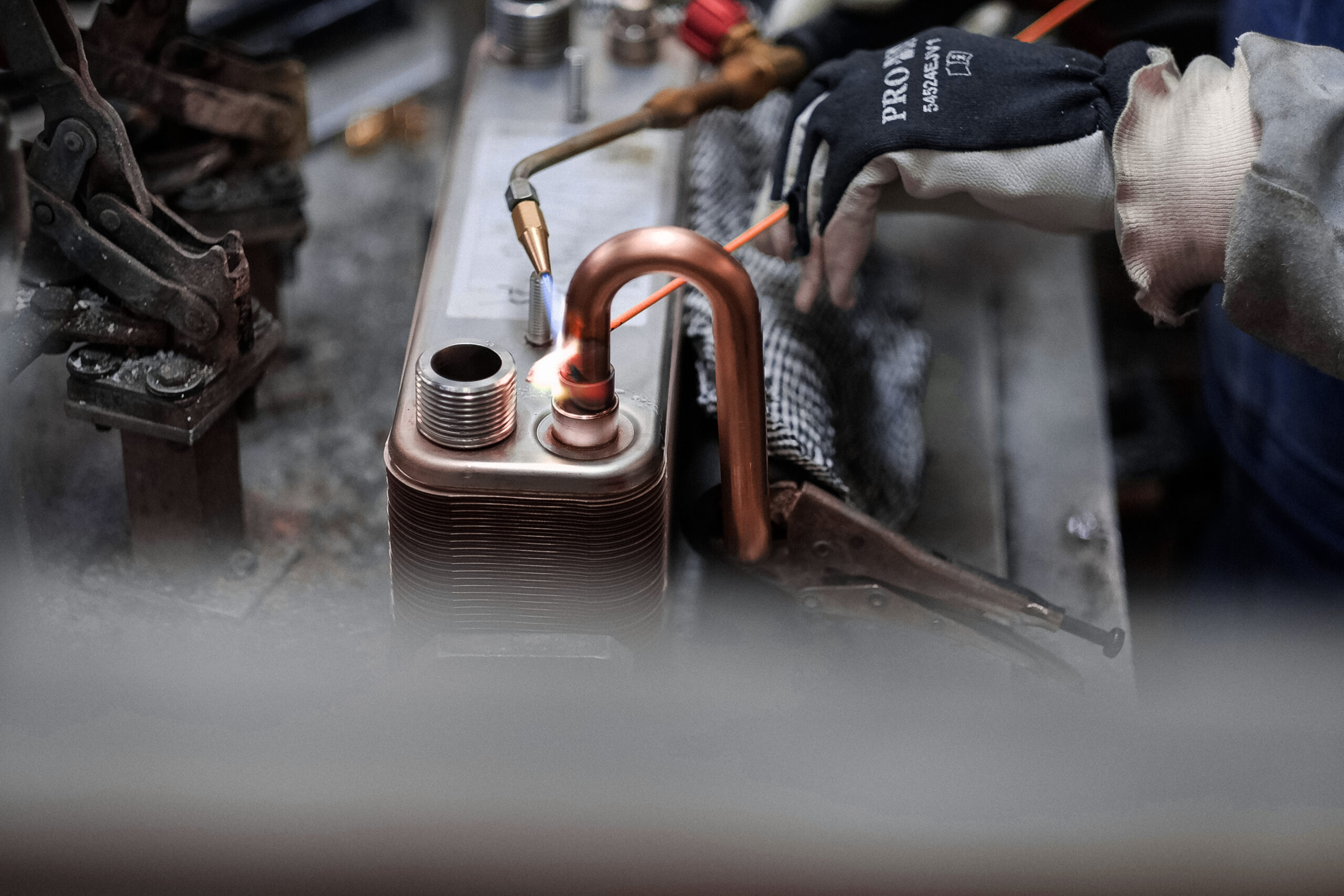

Custom welding and brazing services: expertise that makes the difference

Selectarc puts all its know-how at your disposal to meet your most demanding requirements. We understand that certain projects require special attention and specific skills. This is why we offer a range of tailor-made work services under quality control, designed to meet the most demanding requirements of our customers:

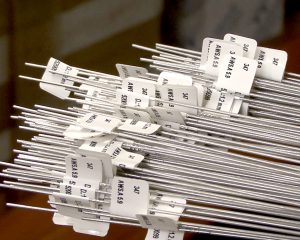

- Wire Drawing: Various diameters for aluminum, stainless steels, nickel, copper, and cobalt alloys

- Dressing and cutting: Precision in all nuances for diameters from 6 to 0.2 mm

- Winding: Ability to wind various alloys in a multitude of diameters, meeting specific needs with a wide range of coils

- Treatment, cleaning, chemical and mechanical stripping: Methods guaranteeing optimum purity of alloys, an essential criterion particularly for the nuclear and aerospace sectors

- Shaping, marking, packaging, heat treatment: Additional services offering customization and adjustment to specific specifications

Tailor-made welding and brazing manufacturing

Our know-how and expertise allow us to develop customized filler product formulations for specific applications by offering the required operating and mechanical performances. These developments thus contribute to advancing the state of the art in the sector.

Our commitment is to provide customized solutions, adapted to each particular request, each specific application with always the highest level of quality requirement.

We offer a wide range of customization possibilities for our welding and brazing filler metals, including:

- Formulation of products to meet specific requirements through our R&D laboratory

- Customization of dimensions such as diameter, length and shape of products

- Customization of coating and alloy color

- The possibility to choose the quantity, size and type of packaging

- Packaging, with particular attention to type, shape, color, as well as vacuum or argon packaging options

- Unique product identification through marking, stamping and flagging options, not to mention personalized labeling

- And the performance of tailor-made tests, in accordance with your specifications

Technical support in welding and brazing

Welding and Brazing Expertise

Do you need technical advice, welding or brazing recommendations, or suitable documentation? Our team of experts is at your disposal to support you and provide you with personalized solutions, adapted to your specific needs.

Technical Support and Process Qualification

We assist you in:

- The choice of filler metals for optimal performance

- The qualification of welding (QMOS) and brazing (QMOB) operating methods

- The optimization of your welding and brazing processes for better quality and durability of assemblies.

Metallurgical Expertise & Quality Control

Thanks to our metallurgical analysis laboratory, we carry out:

- Chemical analyses of the deposited metal

- Mechanical tests (traction, resilience, bending)

- Macrographic and micrographic controls to assess the quality of welds and brazing

Our solutions are adapted to the most demanding sectors, such as aeronautics, nuclear and petrochemicals.