Complete range of high-quality brazing filler metals

Selectarc’s extensive range of brazing products includes innovative and customised alloys for a variety of industrial solutions.

With seven decades of experience, Selectarc is the French leader in the production of brazing filler metals and offers innovative products such as silver tubular brazing wire, aluminium tubular brazing wire and aluminium composite brazing wire. Our state-of-the-art facilities enable us to serve a variety of key industrial sectors.

Our quality brazing filler metals are manufactured exclusively in Burgundy Franche-Comté (France), in our foundry, the only one in France to manufacture brazing filler metals (Cu base) in various forms.

Field of application for our brazing filler metals

Our brazing solutions cover 100% of applications, wherever quality and reliability are essential, particularly in the following sectors:

- Renewable energies

- Transport (automotive, rail)

- HVAC (heating, ventilation, air conditioning and refrigeration)

- Plumbing and sanitary

- Carbide and diamond tools

- Measurement and regulation equipment

- Electromechanical constructions

- Tubular constructions

Brazing product ranges by Selectarc

We offer a wide range of brazing products in different forms to suit every technical application:

- Brazing wires in coils or bobbins

- Bare and coated brazing rods

- TBW rods: Tubular Brazing

- Wire, seamless extruded tube with incorporated flux

- Preforms: rings and various shapes

Our products are available in different alloys: copper-phosphorus, copper-phosphorus-silver, silver, aluminum

- Copper-Phosphorus Brazes: ideal for Copper-Copper assembly, available in bare rods (and coated if necessary).

- Copper-Phosphorus-Silver Brazes: for better electrical conductivity and mechanical resistance, available in bare rods (and coated if necessary).

- Brazing-Soldering Brazes: robust alloys for joining Steel,

- Copper, Cast Iron, available in various formats.

- Silver Brazes: for all ferrous and copper metals, available in bare rods, coated, and preforms, including TBW (Tubular Brazing Wire) technology

- Aluminum Brazes: covering the majority of applications on aluminum, including TBW (Tubular Brazing Wire) and TBMTM (Total Brazing Mix) technologies.

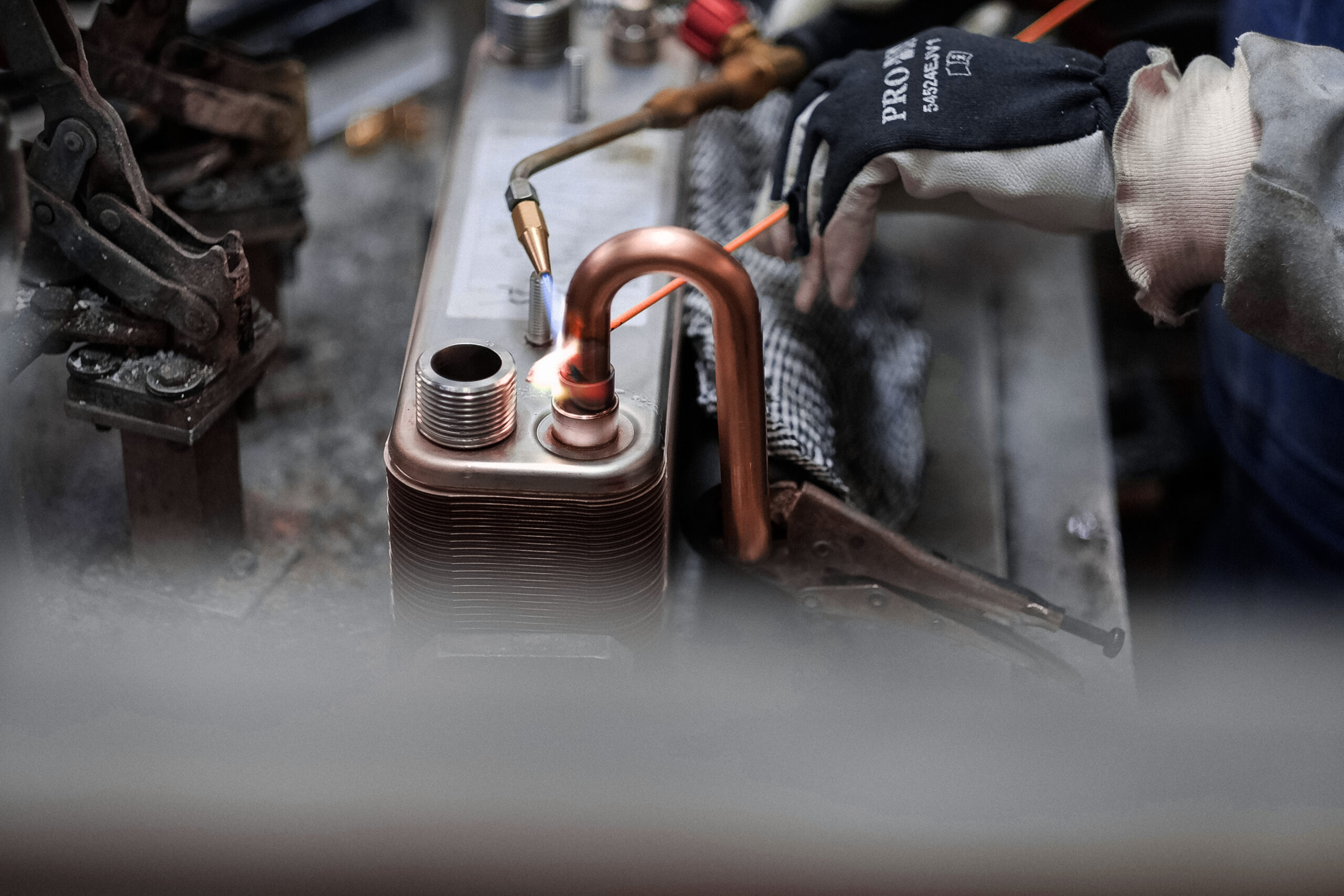

Focus on our TBW (Tubular Brazing Wire)

SELECTARC has developed and patented a unique and innovative solution, the TBW (Tubular Brazing Wire) brazing to optimize your brazing operations.

Made in France, the TBW is a 2 in 1 product that combines a seamless extruded tube with an incorporated flux, thus offering very high fluidity and exceptional mechanical properties.

The advantages of the TBW brazing are:

- High performance: Excellent corrosion resistance and patented process ensuring optimized alloy consumption

- Ease of operation: Ideal for automating brazing operations, it does not require additional flux, thus reducing post-brazing cleaning

- Operator safety: No direct contact with the flux, less smoke and no splashes, ensuring better safety for the operator

Applications are varied: perfect for the HVAC, renewable energy, generators, transformers and electric motors sectors

To go further: a complete guide to brazing in industry

Discover the guide on industrial brazing, co-written by Bulane, Selectarc and Cetim, three major players in the field of brazing and industrial assembly. This document offers an in-depth overview of brazing techniques, an essential process for many industries. It is an essential reference for mastering and optimizing brazing processes for all professionals in the industry.

This guide covers in depth all aspects of industrial brazing, including definitions, techniques, materials and gases used, as well as standards and safety. It also explores the industrial sectors concerned and recent innovations in the field.

4 highlights of this guide:

- Process optimization: highlighting advanced techniques to optimize industrial brazing operations and achieve better productivity

- Increased operator safety: presentation of the different brazing methods (induction, oxyhydrogen flame, etc.) as well as training and standards applicable to brazing

- Innovative technology: advantages of TBW technology (Tubular Brazing Wire, patented process) in terms of reducing fume emissions and optimizing brazing operations

- Environmental sustainability: exploration of sustainable brazing processes that meet the crucial challenges of decarbonizing industry, such as Dyoflam brazing stations, allowing a 94% reduction in the environmental impact of brazing operations.

Environmental commitment

In accordance with EU regulation No. 494/2011 of 20 May 2011, Selectarc has eliminated the use of strong brazing agents containing cadmium, offering safe and effective alternatives. To see our entire range of brazing products, visit our brazing overview.