Full range of high performance welding filler metals

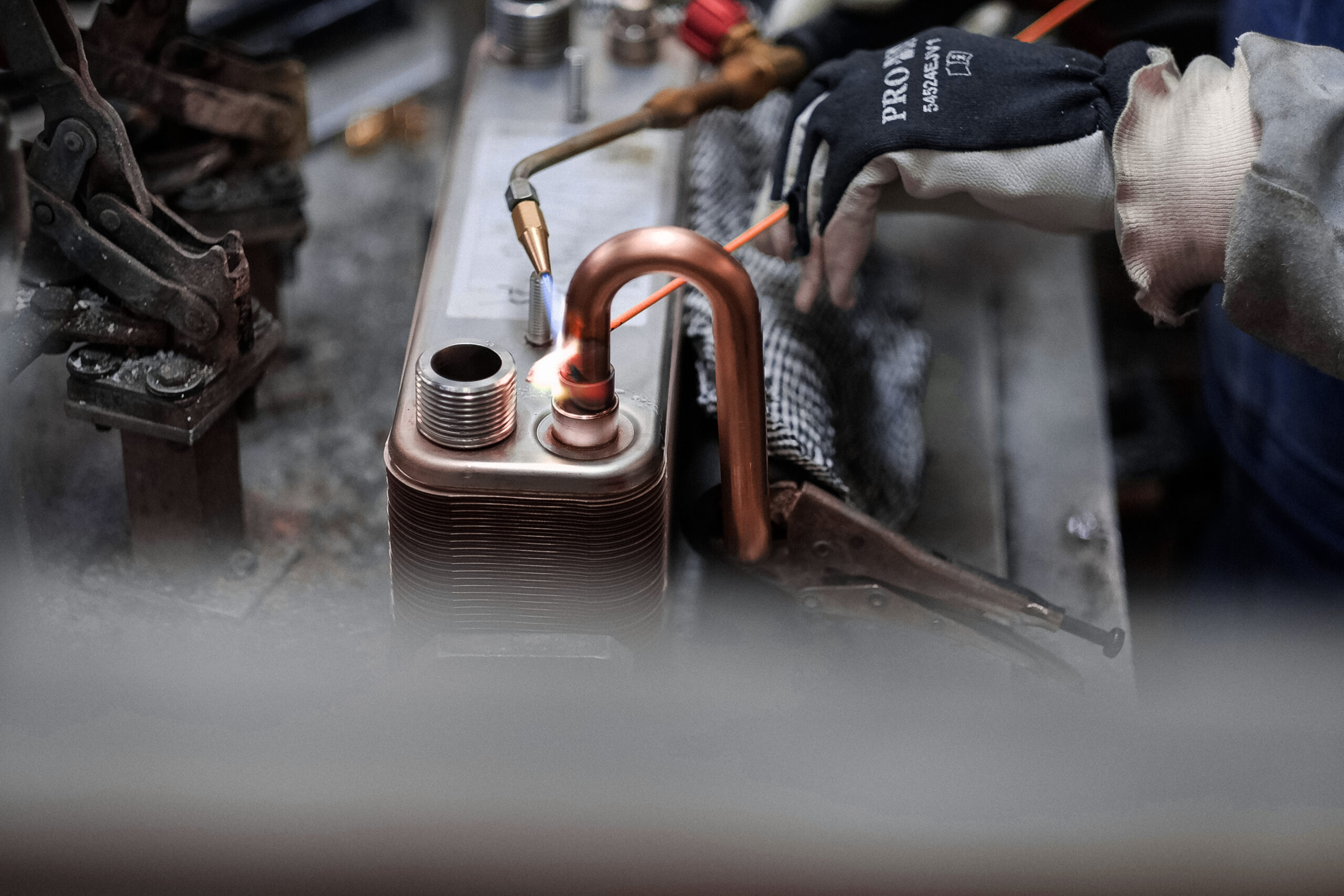

Selectarc offers a wide range of welding products: coated electrodes, MIG/MAG wires, TIG rods and wires, special wires, micro-laser range and more, adapted to various sectors, both conventional and strategic.

Since 1952, Selectarc has established itself as the French manufacturer reference for welding and brazing filler metals, with an ancestral know-how recognised worldwide. Our catalogue includes a wide selection of products designed to meet the most stringent requirements of different industrial sectors.

A wide range of welding products

Our comprehensive range includes coated arc welding electrodes, welding wires such as TIG rods, MIG/MAG wires, sub-flux or flux-cored, and special wires.

Our products are distinguished by their ability to meet the specific needs of a wide range of sectors, including :

- Energy, including nuclear and renewable energies

- Defence, particularly naval

- Transport, in particular aeronautics, where Selectarc excels with its SAFRAN approval

- Maintenance, repair and reloading for the mineral, forging, steelmaking and chemical industries

Our arc welding electrodes

Our coated electrodes for electric arc welding are developed and manufactured to ensure optimum performance.

From ordinary steel to the highest-performance alloys, the Selectarc range offers a solution for the most delicate assemblies.

- Rutile, basic, cellulosic electrodes, miscellaneous

- Basic electrodes for non-alloy steels

- Basic electrodes for high yield strength steels

- Basic electrodes for heat-resistant steels

- Basic electrodes for cold-resisting steels

- Stainless steels

- Cast iron alloys

- Nickel alloys

- Aluminium alloys

- Copper alloys

- Maintenance & repair, reloading

- Miscellaneous (cutting and chamfering/gouging)

Our plain MIG/MAG welding wires

Selectarc’s MIG/MAG wire production system ensures consistency in the characteristics of its wires: no fluctuation in diameter, state-of-the-art winding, various parameters that guarantee product performance.

- Non-alloy steels

- Low-alloy steels

- Low-alloy steels: aeronautical range

- Stainless steels

- Nickel alloys

- Aluminium alloys

- Copper alloys

- Titanium alloys

- Cobalt alloys

- Cobalt alloys: aerospace range

- Maintenance and repair, hardfacing

Our TIG welding wires and rods

Our TIG wires and rods are ideal for applications requiring extreme precision.

With its TIG wire cleaning system, Selectarc is a key supplier to the aerospace, nuclear and high-tech markets.

- Non-alloy steels

- Low-alloy steels

- Low-alloy steels: aerospace range

- Stainless steels

- Nickel alloys

- Aluminium alloys

- Magnesium alloys

- Copper alloys

- Titanium alloys

- Cobalt alloys

- Cobalt alloys: aerospace range

- Maintenance and repair, hardfacing

- Miscellaneous (TIG Orbital)

Our TIG welding wires and rods

Using a tubular cored wire instead of a solid wire or coated electrode improves welding performance while maintaining quality.

Our range of cored wires (gas-shielded and gas-insulated) for joining and hardfacing non-alloy and low-alloy steels complements our extensive range of welding consumables:

- Non-alloy steels

- Low-alloy steels

- Stainless steels

- Nickel alloys

- Cast iron

- Cobalt alloys

- Reloading

Advantages of the SELECTARC range :

- Easy to use

- Higher productivity

- Consistent weld quality

- High welding speed

- Good current transfer

- Good bead appearance

- Low diffusible hydrogen

- Excellent reliability (fewer welding faults)

- Very good mechanical characteristics

- Can be welded in any position (for certain references)

Our range of micro-laser welding wires

We also offer innovative solutions such as micro-laser welding wires for precision applications used in the automotive, electronics, aerospace, medical and jewellery industries.

Our range of filler products is available from a diameter of 0.2 mm, packaged in wire or coils, in the following grades:

- Low-alloy steels

- Stainless steels

- Nickel alloys

- Aluminium alloys

- Copper alloys

- Titanium alloys

- Cobalt alloys

- Hardfacing for tooling

Welding Excellence: Our Commitment to Quality and Innovation

As well as supplying products, we are committed to offering solutions that improve the quality, performance and productivity of our customers.

Our advanced manufacturing process guarantees the consistency and reliability of the products we offer.

Our two factories are ISO 9001 and 19443 certified. These two certifications strengthen the confidence of our customers and partners, ensuring maximum efficiency and a constant concern for quality and safety. At Selectarc, we are committed to continuously improving our processes to exceed our customers’ expectations.

Whether you’re looking for specific products for delicate applications or want to find out more about our range, our team is here to help you find the solutions that best meet your needs. Contact us today to discuss your welding and brazing projects.

Browse our site to find out more about what we have to offer and how we can contribute to the success of your projects.